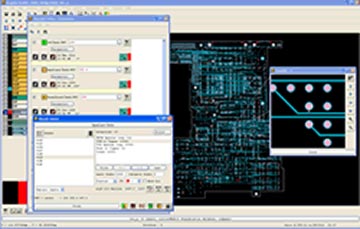

P-C-D utilise the Valor NPI tool to verify Printed Circuit Board (PCB) database outputs before the manufacturing process commences.

Resolve manufacturability issues early in the process to save time and money.

For PCB designers, Valor NPI provides concurrent DFM analysis during the design process, applying up to 700 manufacturing rules to your design to ensure minimum revision spins in manufacturing. The DFM analysis flow can be set up to automatically analyse each new version and pinpoint all potential manufacturing problems directly in the CAD system. For manufacturing NPI and process engineers, Valor NPI provides comprehensive analysis of how new products match the fabrication, assembly and test processes, including VPL (Valor Parts Library) analysis, for rapid feedback to the customer.

The Valor NPI tool verifies Printed Circuit Board (PCB) database outputs before the manufacturing process commences.

Resolves manufacturability issues early in the process to save time and money.